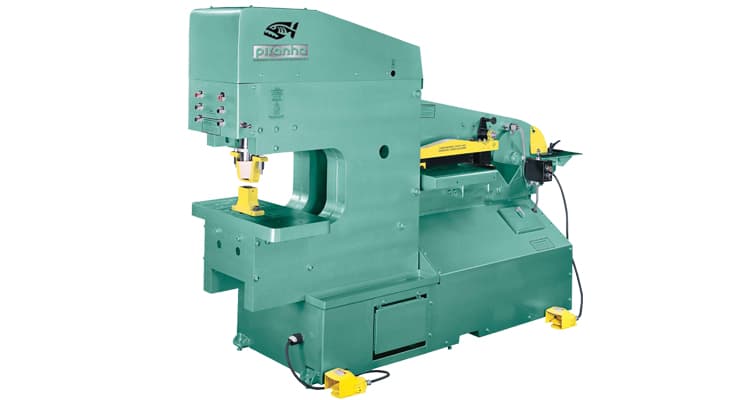

The P-65 Piranha Ironworker unique automatic urethane hold downs eliminate time spent on adjustments during shear cuts, they also effectively keep flat stock and sheet metal from distorting during operation. Faster cycle times and less distortion mean value added benefits. These standard features save metal fabricators time and money, bringing value to every fab shop.

The P-90 Piranha Ironworker dovetail slide allows steel fabricators to switch from punching to bending, easily and efficiently. Metalworking machine shops everywhere have come to appreciate Piranha’s Quick-Change Tooling. Likewise, the urethane strippers almost eliminate part distortion, while minimizing stroke length. These standard features, plus more horsepower per ton, is why Piranha Ironworker machines lead the competition.